AUTOMATIC FOLDER GLUER/STITCHING MACHINE

Special cardboard requires instructions before ordering the machine

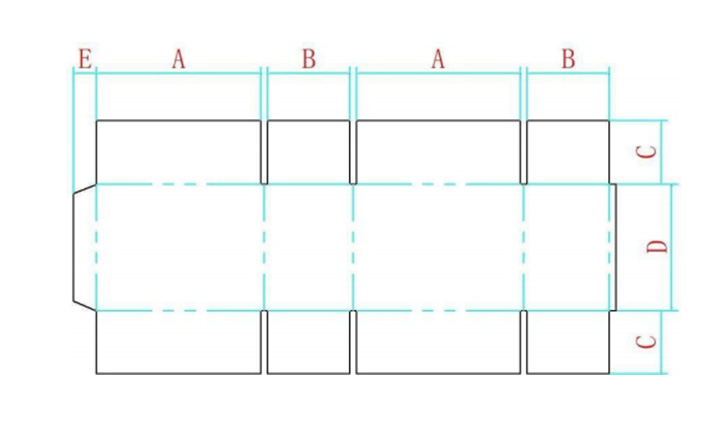

The size of Stitching :

| Max. Length (A+B)*2 | 2600 mm (Stitching) |

| Min. Length (A+B)*2 | 760 mm |

| Max. Height (C+D+C) | 1200 mm |

| Min. Height (C+D+C) | 300-350 mm |

| Stacking Height | 400 mm |

| Box Length | A Max. 800 mm / A Min. 200 mm |

| Box Width | B Max. 500 mm / B Min. 200 mm |

| Box Height | D Max. 600 mm / D Min. 120 mm |

| Box Lid | C Max. 275 mm / C Min. 60 mm |

| E | E Nail 35-40 mm |

The size of gluing :

| Max. length (A+B)*2 | 2600 mm (Gluing) |

| Min. length (A+B)*2 | 420 mm |

| Max. Height (C+D+C) | 1200 mm |

| Min. Height (C+D+C) | 170 mm |

| Stacking Height | 400 mm |

| Box Length | A Max. 800 mm / A Min. 130 mm |

| Box Width | B Max. 500 mm / B Min. 80 mm |

| Box Height | D Max. 600 mm / D Min. 120 mm |

| Box Lid | C Max. 300 mm / C Min. 60 mm |

| E Stander 40 mm glue wheel 30 mm |

Paste wheel (20 mm - 30 mm can be customized) Please explain in advance |

Specification:

| Working Power | 6 HP |

| Length of Machine | 14500 mm |

| Width of Machine | 4100 mm |

| Weight of Machine | ≈6.3T |

| Speed of Machine |

0 - 150 m/min (Depends on the previous process, cardboard size and quality) |

| Nail distance | 30 - 100 mm |

| No. Of Nail | 1 - 99 nails |

Specification:

The fully automatic all-in-one nailing machine is composed of four parts: paper feeding part, folding part, box nailing part, and counting and stacking part. Frequency conversion speed regulation, simple and reliable operation. Digital display control, PLC computer amplitude modulation, dual frequency conversion synchronous operation, simple, fast, reliable and accurate control mode, automatic paper feeding,

Automatic counting, automatic nailing, automatic stacking output, high efficiency and energy saving, saving labor costs.